Description

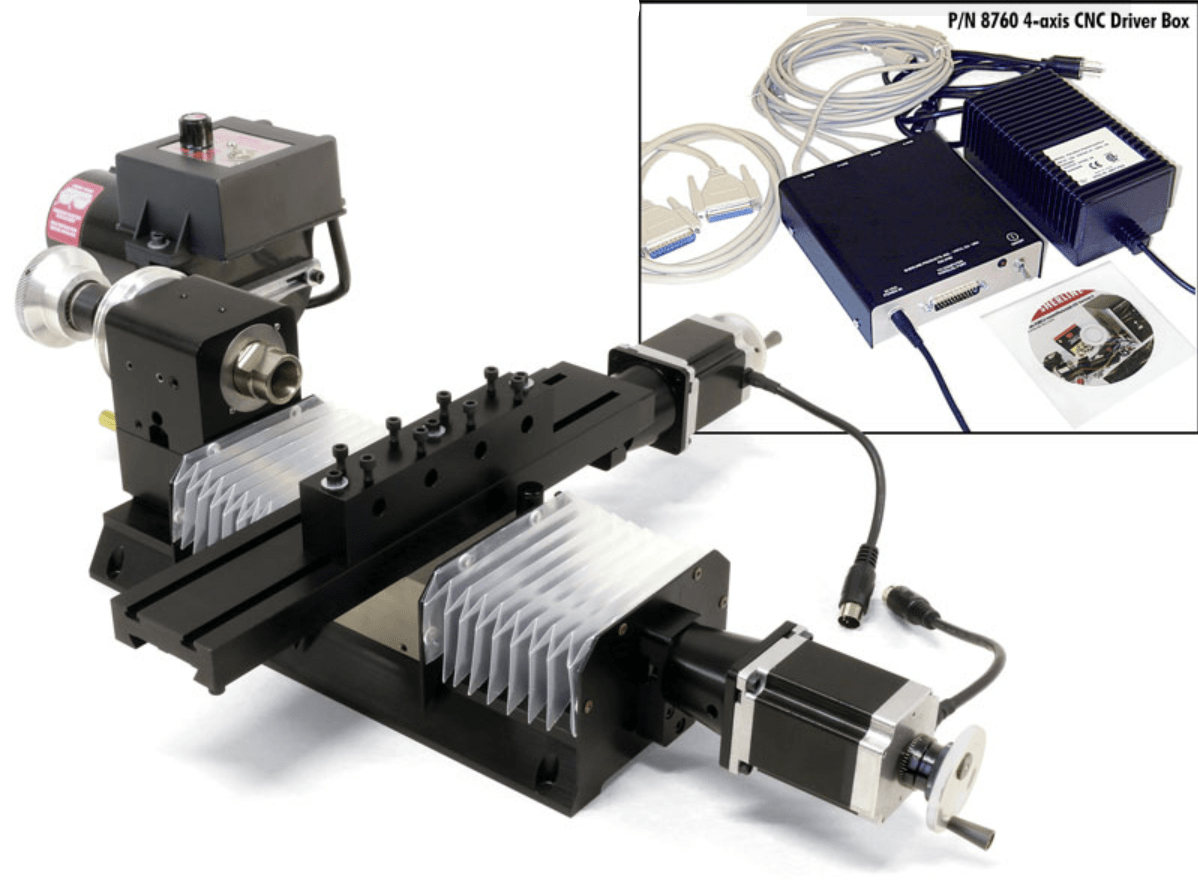

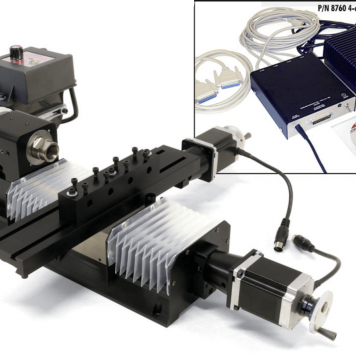

Sherline Industrial CNC Chucker Lathe with Driver Box 6620

Industrial CNC Chucker Lathe with Driver Box – PRICE WILL VARY BASED ON OPTIONS, WE WILL EMAIL OR CALL YOU WITH SPECIFIC AND FINAL PRICE.

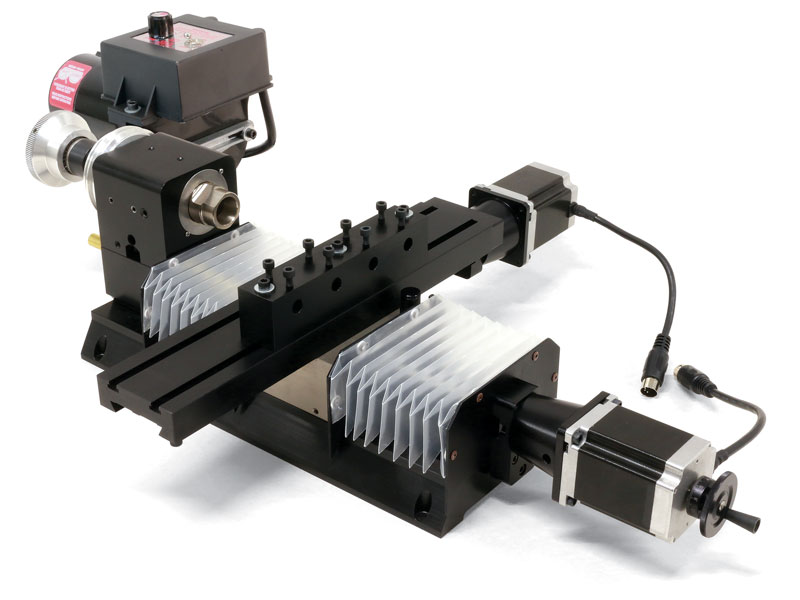

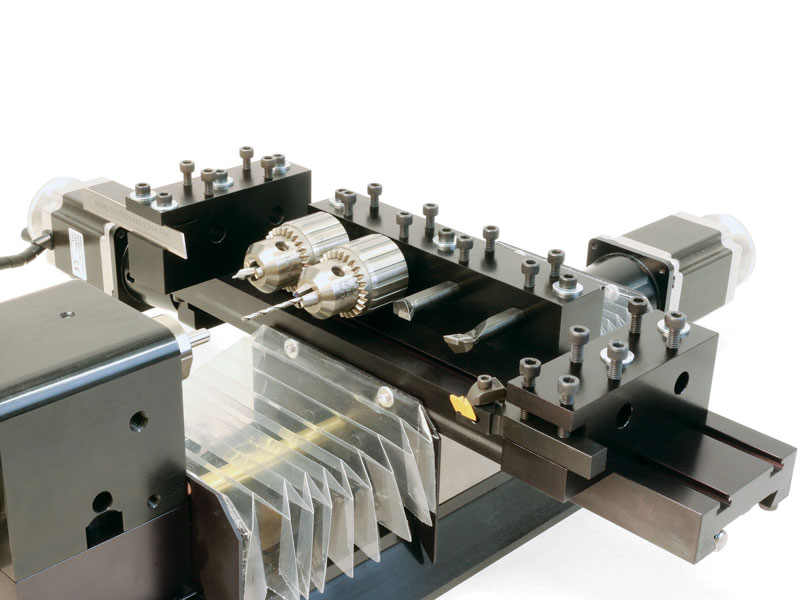

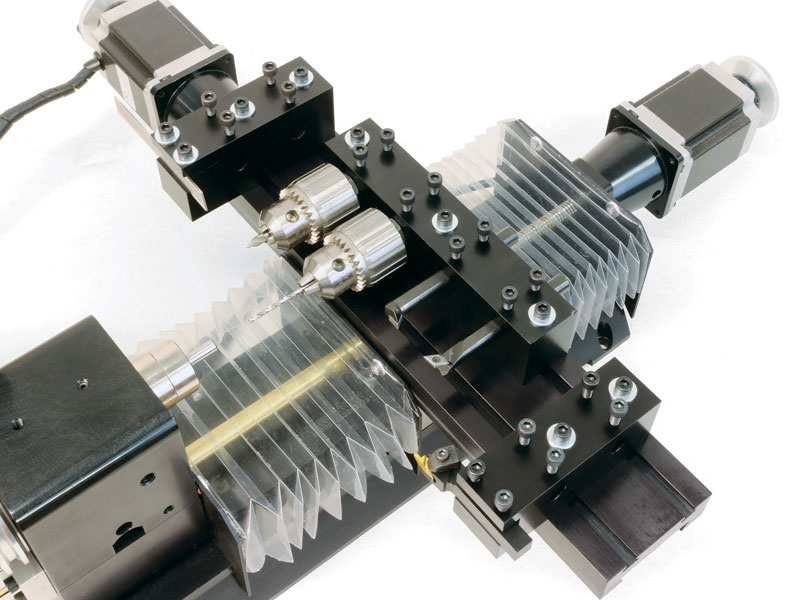

Sherline designed their CNC chucker lathe for their industrial customers who want the convenience of using multiple tools in a single set-up. The lathe has a 13″ crosslide that accommodates the 3/8″ gang-tooling tool post and two, optional tool posts that can be used for boring and parting tools (tools not included).

Standard Features Of Chucker Lathe Include

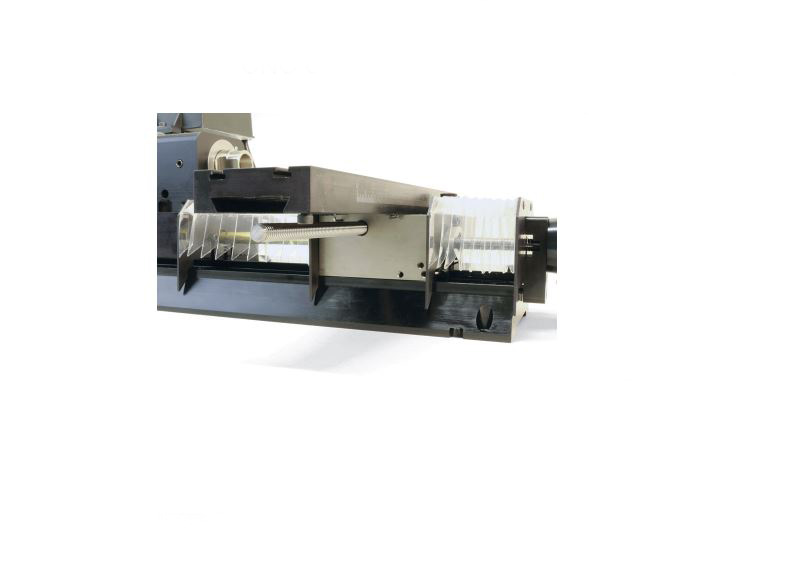

- Ball Lead Screw: Rolled Ball Screw with BSH Nut .10mm Diameter, 2mm Lead. C7 Accuracy, P1 Preload. The linear accuracy is 50 micrometers/300mm

- 3/8″ Gang-tooling tool post, which holds up to four tools

- 14″ Base

- 13″ Mill table

- Mill Saddle: Has electroless nickel coating with Teflon. This offers a hard surface that is rust proof. The Teflon offers a friction coefficient of .1-.2u for smoother movement of the saddle and the table.

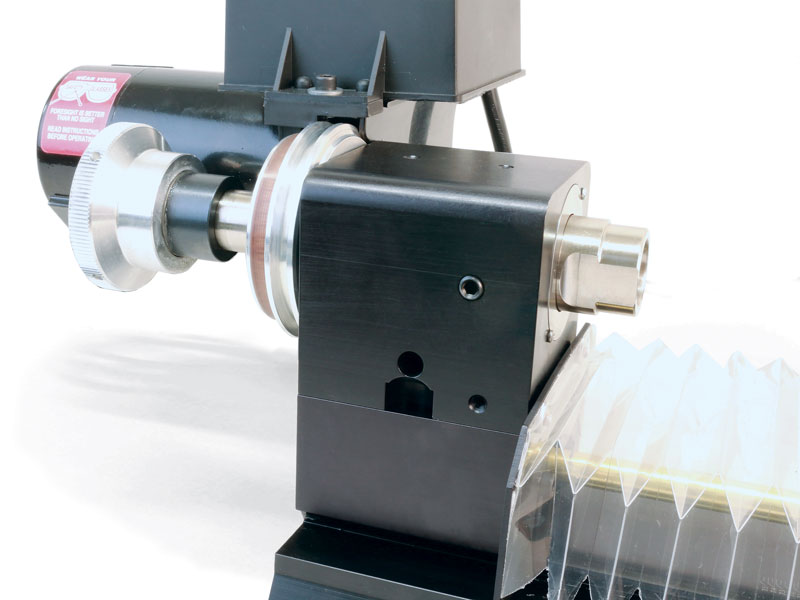

- 3C Collet headstock: TIR (total indicator runout) is rated at .0005, or less on the 3C headstock. In addition, the 3C spindle is electroless nickel plated to aid in rust prevention, and to increase the surface hardness of the spindle for durability.

- Powerful 90V DC motor with electronic speed controller

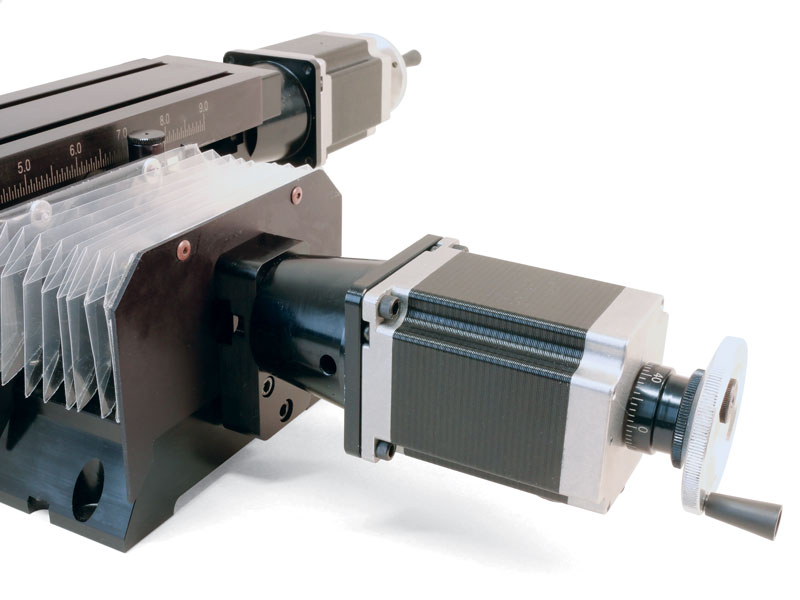

- Two, 2-amp high-torque stepper motors

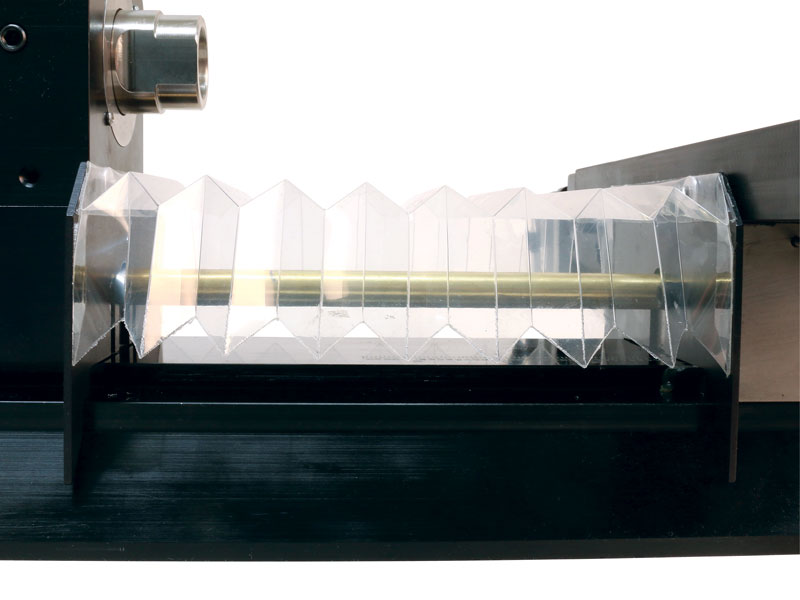

- Accordion way cover and brass-tube leadscrew cover

- Maximum feed rate is 32 in/min.

- Largest diameter through the collet is ½” (13mm). NOTE: collets are not available through Sherline Products.

Included Components

- Driver box (Converts g-code to steps to run DC stepper motors)

- Output cables for X, Y, Z and A pre-wired with DIN plugs for stepper motors

- 3.7 amp, 24 volt power supply with cord, works on 115 or 240 VAC

- 25-pin parallel cable*

- 2 CD set with Linux/EMC2, utilities and instructions

- Two spare fuses

NOTE: A 25-wire parallel port is required because EMC2 is designed to be capable of running up to six axes simultaneously. Even though the Sherline driver box only uses four of those axes at one time, a 2-wire serial USB port cannot transmit data to multiple axes fast enough for glitch-free CNC operation.

Minimum Computer Requirements

In order to install and run a Linux based system from the disc provided it is recommended the computer have at least the following minimum specifications:

- Processor speed: 800 MHz or faster (Pentium III class or equivalent processor)

- RAM: 512 Mb (Sherline provides 1 Gb)

- Hard Drive: 20 Gb or larger

- 25-pin parallel port (printer port)

- (Laptop computers are not recommended.)

Stepper Motor Specifications

- Frame size: NEMA #23

- Shaft: 1/4″ diameter, dual shafts

- Holding Torque: 1.35 N.m (Newton meters), 13.756 kg-cm (kilogram centimeter), 191.17 oz/in (ounce inch), 11.948 in/lb (inch pound)

- Axial-Force: Fa=15 N Max., or 3.37 lbf Max.

- Radial-Force: Fr=75 N Max., or 16.86 lbf Max.

- Rotor inertia: 480 g-cm2

- Voltage: 4.5 V DC

- Current: 2 A

- Step Angle: 1.8° (200 steps/rev)

Ball Screw Machine Specifications

- Swing Over Base 4.950″ (125.7 mm)

- Swing Over Table 1.875″ (47.6 mm)

- Hole Through Spindle .5″ (12.7 mm)

- Spindle Nose 3C Taper 24 degrees

- Spindle Runout of 3C Taper .001″ or less (.0005” or less upon request for an additional charge)

- Travel of X-axis 7.8″ (198.1mm)

- Travel of Z-axis 5.8″ (147 mm) (from end of base to front of spindle nose); 6.5″ (165mm) total travel.

- Handwheel Graduations .02 mm

- Dimensions (Measurement given are for CNC-ready machines only)

- Length Overall 22.625″ (574.7 mm) (add 4.625″ for a Sherline high-torque stepper motor)

- Width Overall 15.375″ (340 mm) (add 4.625″ for a Sherline high-torque stepper motor)

- Height Overall 8.875″ (225.4 mm)

- Shipping Weight 51 lbs. (23.2 kg)

- Motor 90 volt DC with electronic speed control that accepts any incoming current from 100VAC to 240 VAC, 50 Hz or 60 Hz.

- Spindle Speed Range 70-2800 RPM continuously variable by electronic speed control

PLEASE NOTE – MOUNTED TOOLS ARE NOT INCLUDED. PLEASE ALLOW 3-4 WEEKS LEAD TIME FOR SHIPPING