Description

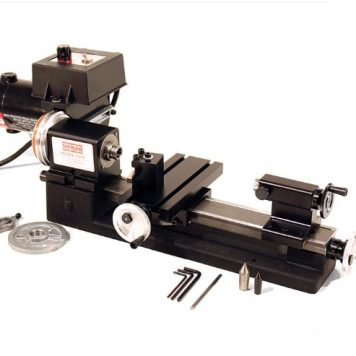

Sherline 14″ 8-direction Benchtop Mill 2000 w/Servo 550W Motor Upgrade

Includes mill shown in 2nd picture

Includes an upgraded, supercharged motor for Sherline mills featuring a simple 4 bolt assembly! The deluxe 8-direction milling machine offers the most versatility of any Sherline mill. In addition to the X-, Y-, and Z-axes of travel, there are five additional directions that the headstock spindle can be positioned to do drilling or milling on your part from virtually any angle. The headstock can pivot up to 90° in either direction. The column bed can be rotated side-to-side up to 90° in either direction for angled drilling. A special knuckle allows the column to be pivoted front to rear. The “ram” design of the column base also allows the entire ram to be pivoted up to 90° side-to-side. Loosening the column cap allows the ram to be moved in and out with over 5.5″ of travel.

With this many directions of movement, the machining possibilities are virtually limitless within the size capabilities of the machine. The 14″ long base also increases Y-axis travel by an additional 2″ compared to the Model 5400 mill. This is the milling machine for those who want to take their miniature machining abilities to the extreme.

Our 8-direction benchtop mill is perfect for the customer looking for a mini milling machine to make small, precision parts. All our milling machines are made in the USA, and our customer service is second to none. Although our machines are small, they can produce high-quality precision parts. Our 14″ benchtop mill will not only cut wood and plastic but is also rigid and accurate enough to cut aluminum and steel parts. This mini mill is a desktop-size machine with full-size machine precision and accuracy.

Includes:

- 14″ base

- 550 Watt servo motor with 4.4 NM torque

- 2024 Base control unit

- Custom welded motor mount with adjustable support leg

- 2 speed stepped pulley

- 2″ (51mm) resettable, zero adjustable handwheels on the X- and Y-axes, and one 2-1/2″ (63mm) resettable, zero adjustable handwheel on the Z-axis. Each handwheel has laser-engraved aluminum handwheel collars

- 2.75″ (70 mm) x 13.0″ (330 mm) table with two T-slots

- ¼” Drill Chuck w/ key, #1 Morse arbor with drawbolt

- 2″ column riser block

- Laser-engraved scales on the base and table

- Pulleys, drive belt, three hexagonal keys, spindle bars, gib removal tool, eight-foot three-wire power cord, and instruction manual

- Oil reservoirs on the X/Y axes and the Z axis help keep critical parts lubricated. These were initially developed for CNC machines that run constantly for hours on end but can benefit manual machines as well

- Brass leadscrew cover that keeps chips off the rear of the Y-axis leadscrew

[su_button url=”http://www.vcshobbies.com/blog/sherline-mill-documentation/” background=”#f7921c” center=”yes” class=”vcshobbies-button”]Click Here For Instructions[/su_button]