Description

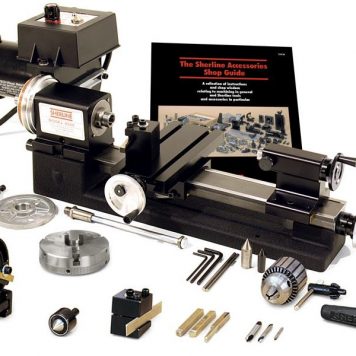

Sherline Deluxe Mill “A” Package 5400A

Deluxe Mill “A” Package

The main difference between a lathe and a mill is that on a lathe, the work turns and the cutting tool is stationary, while on a mill, the tool turns and the work is stationary. Because of the tremendous number of operations that can be performed on a vertical mill, it is commonly regarded as the most important tool in the modern machine shop…the workhorse of the industry.

The deluxe mill is our most popular mill. It comes equipped with all of Sherline’s standard features upgraded to include a laser engraved 12″ (305mm) solid aluminum base for 2″ of additional Y-axis travel, laser engraved scales on the table and base, 2-1/2″ (63mm) adjustable “zero” handwheel on the Z-axis and 2″ (51mm) adjustable “zero” handwheels on the X- and Y-axes, a mill headstock spacer to provide more throat distance and a 1/4″ drill chuck and drawbolt.

All Sherline mills feature precision machined dovetailed slides with adjustable gibs, permanently lubricated spindle bearings, adjustable preload anti-backlash feed screws and a high-torque 90V DC motor with electronic speed control. Speed is continuously variable from 70 to 2800 RPM without gear or belt changes. A second pulley position is also available to provide extra torque at low RPM if needed.

New Mill Features

- Oil reservoirs on the X/Y axes and the Z-axis to help keep critical parts lubricated. These were initially developed for CNC machines that run constantly for hours on end but can benefit manual machines as well

- Brass leadscrew cover that keeps chips off the rear of the Y-axis leadscrew

Features of the Deluxe Mill…

The deluxe mill offers the same standard features as the Model 5000/5100 mill except for the following upgrades: 12″ base with two extra inches of Y-axis travel (5″ instead of 3″), adjustable “zero” handwheels, 1/4″ drill chuck and laser-engraved reference scales on the base and table.

Standard equipment for the mill includes:

- A powerful 90V DC motor with electronic speed controller

- 12″ base

- 2-1/2″ (63mm) adjustable “zero” handwheel on the Z-axis and 2″ (51mm) adjustable “zero” handwheels on the X- and Y-axes

- 2.75″ (70 mm) x 13.0″ (330 mm) table with two T-slots

- Pulleys, drive belt, three hexagonal keys, spindle bars, gib removal tool, eight-foot three-wire power cord, and instruction manual

- Headstock spacer block

- ¼” Drill Chuck w/ key, #1 Morse arbor with drawbolt

5400 “A” Package Includes:

- 3072 1/4″ Jacobs Drill Chuck w/ #1 Morse Arbor, Key, and Drawbolt

- 3013 Step Block Hold-down Set

- 3020 5/32″ Sherline Hex T-Driver

- 3021 3 pc. Center Drill Set

- 3052 Fly Cutter w/ 1/4″ Carbide Cutting Tool

- 3060 3-pc. Mill Collet Set w/ Drawbolt

- 3079 3/8″ End Mill Holder

- 3551 Milling vise

- 5327 Sherline Accessories Shop Guide book

- 7400 6-pc. 3/8″ Shank End Mill Set

CNC AND DRO VERSIONS AVAILABLE FOR AN ADDITIONAL COST, PLEASE EMAIL FOR DETAILS